RackStacker

Overview

The Challenge: Potential Work Comp Claims and Labor Health

One of the most labor-intensive and potentially harmful jobs in a bottled water plant is manually lifting filled 5-gallon bottles into bottle racks. Racks are often used in the large bottled water industry to load into delivery vehicles. Bottles weigh 40 lbs, and bottles must be lifted into the upper rack, which may exceed 68″. These vast stresses on the operator lead to potential worker’s compensation claims and long-term operator injury and health issues.

Norland’s Solution: A Unique & Efficient Design

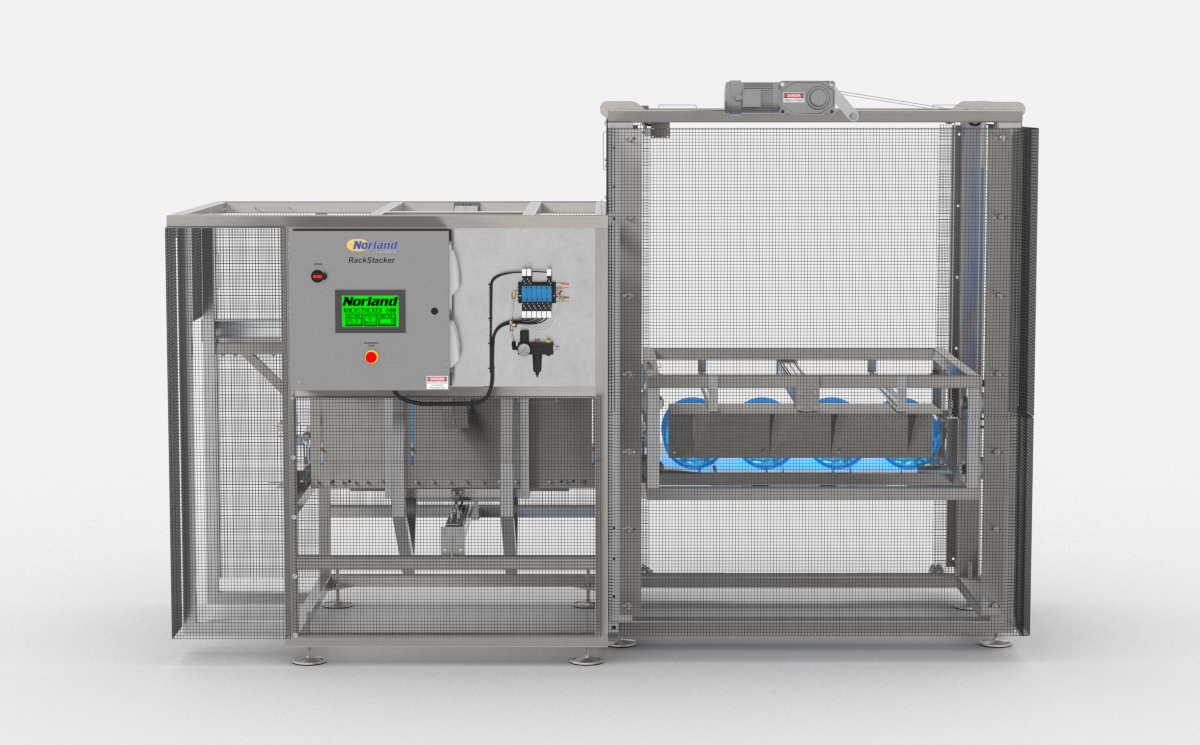

The RackStacker is a perfect partner for your large bottle water machines. This automatic, multi-function, plastic bottled water racking system capable of stacking 3-5 gallon returnable bottles into various bottle racks, capable of up to 600 bottles per hour. It eliminates manual lifting and loading of 3 gallon bottles and 5 gallon bottles, greatly reducing the possibility of Worker Comp claims while improving employee safety and increasing production efficiency. Designed and built with a proprietary bottle alignment system, the RackStacker Bottle Racking System’s accuracy and reliability are unmatched. This highly efficient stacking machine is easy to use, compatible with most rack styles, and easily integrates into your current production line’s large water machine. Add the RackStacker to your large bottling plant layout and experience how hassle-free your water bottle packing can be.

Features

- Racks up to 600 BPH

- Programmable with up to 3 different rack styles

- Automatic and manual bottle feed conveyor options

- Bottle pre-load tilt & bottle lift/load easily orient bottles for rack

- PLC and Solid State Controls

Check Out Every Angle

Have Questions? Interested in a Quote?

Whether you have questions or would like a quote on a new RackStacker, our sales team is here to help. Feel free to drop us a line via one of the buttons below.

Request A Quote

Triton160

Triton160  Triton450

Triton450  BWF150

BWF150